THE COMPOST POWER HOUSE

PROJECT INTRODUCTION:

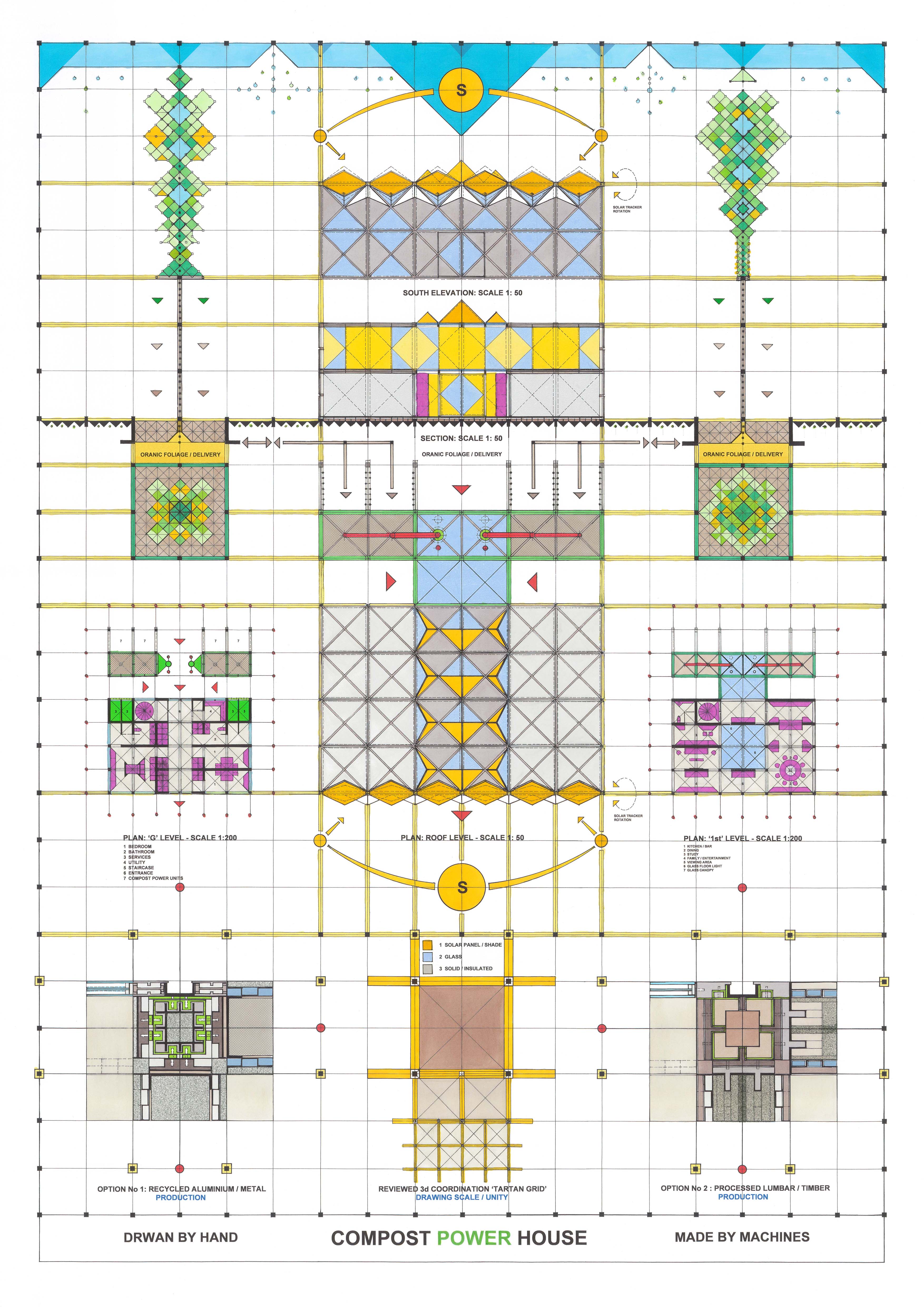

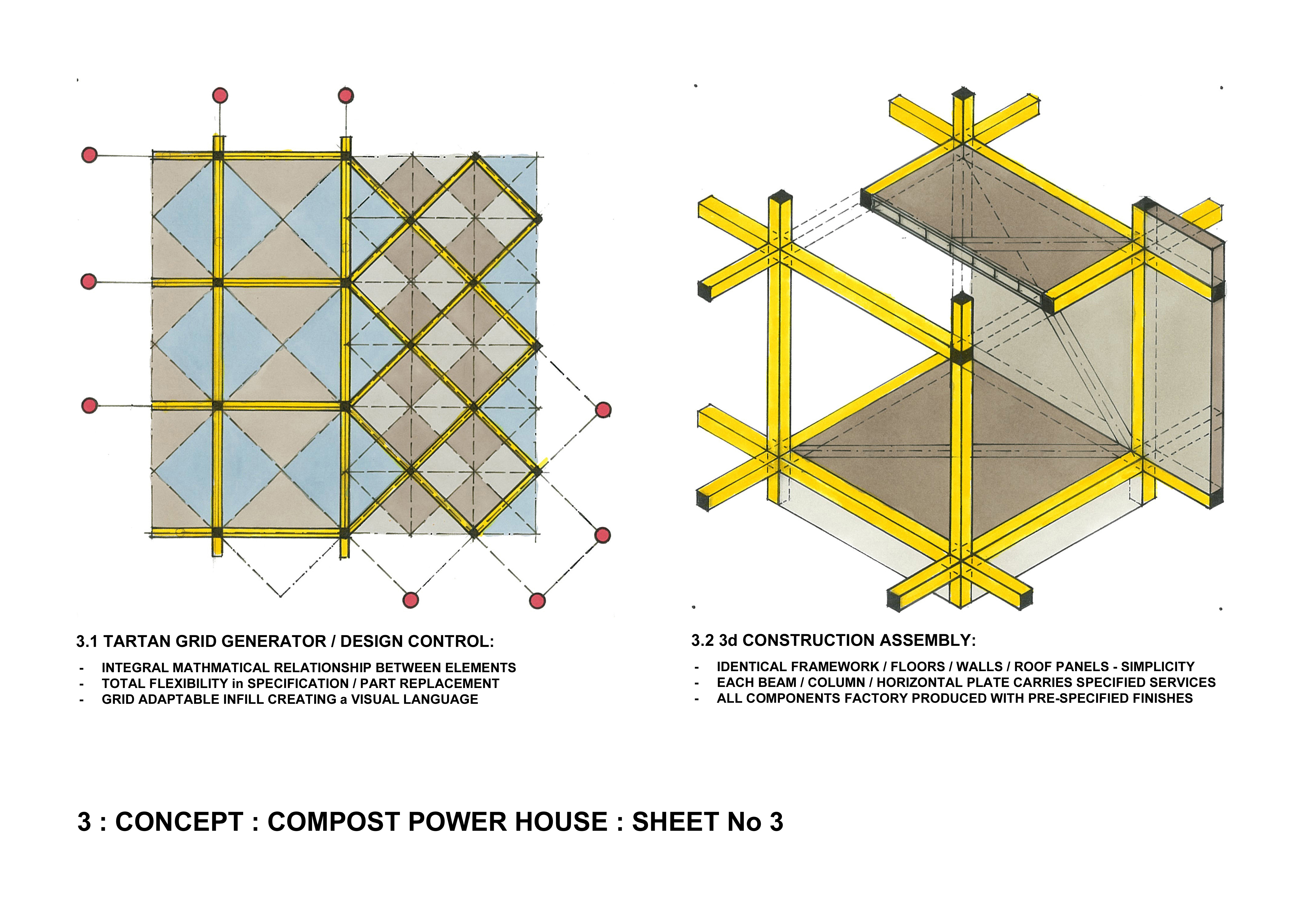

The ‘Compost Power House’ (CPH) explores a solution resolving todays shortages in housing. Firstly, it revisits the 1944 principles of ‘AIROH’, Mass Industrialised Housing’ created as an adaptable kit of parts. Secondly, the historic ‘Tartan Design Grid’ (TDG) and thirdly, the manipulation of ‘Aerobic Decomposition’ (composting).

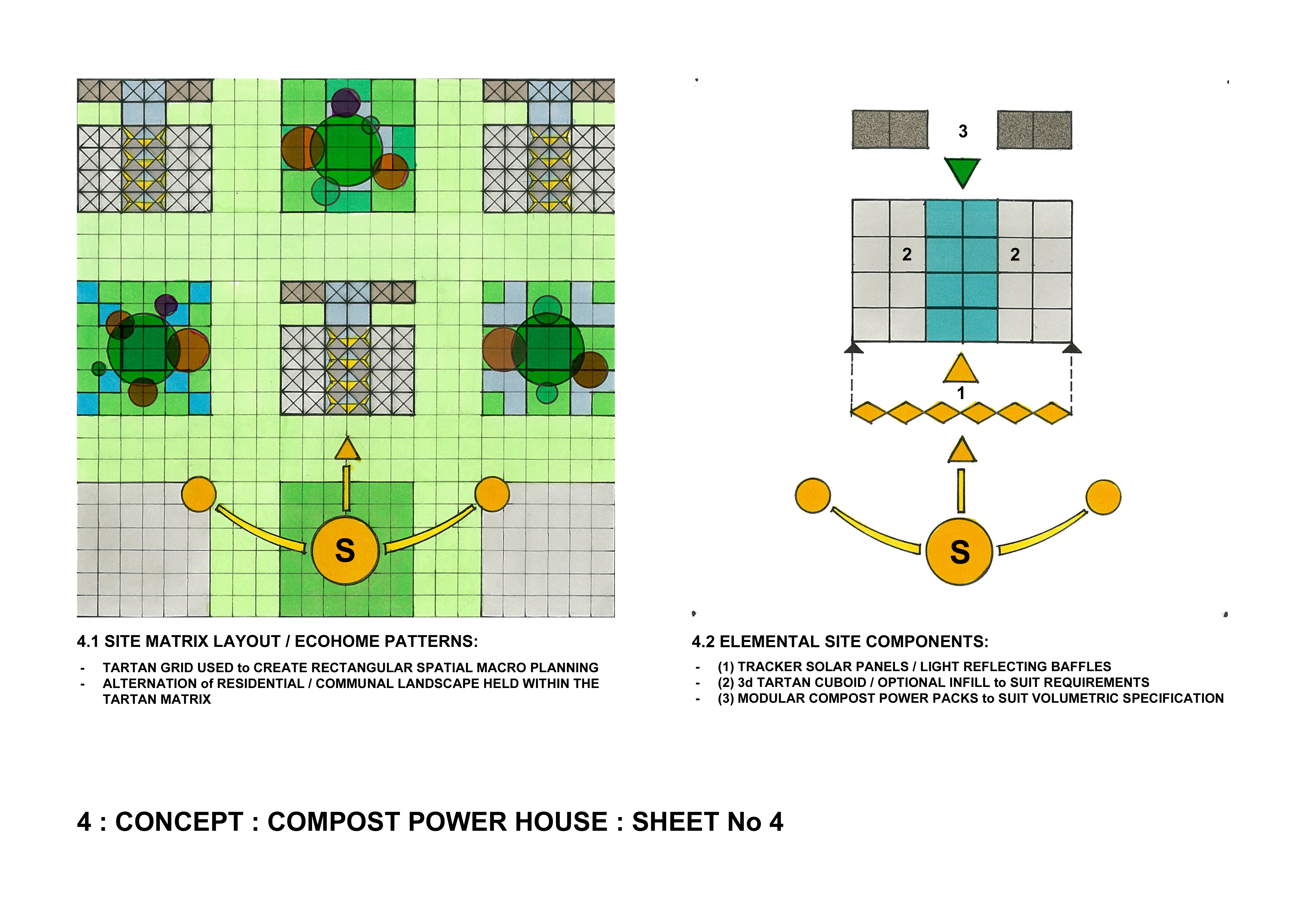

Historically, TDG is seen in the Greek / Roman era, contemporary applied in urban planning and architecture. It superimposes layers forming the site plan, groundscape layout, spatial planning and constructional assembly. Low illumination activities are located at ground level (bedrooms, bathrooms, utilities.), higher ones at the 1st (family, living, guests.). The cellular rooms are formed by a structural panel system- material choices impacted through performance and wellbeing choices.

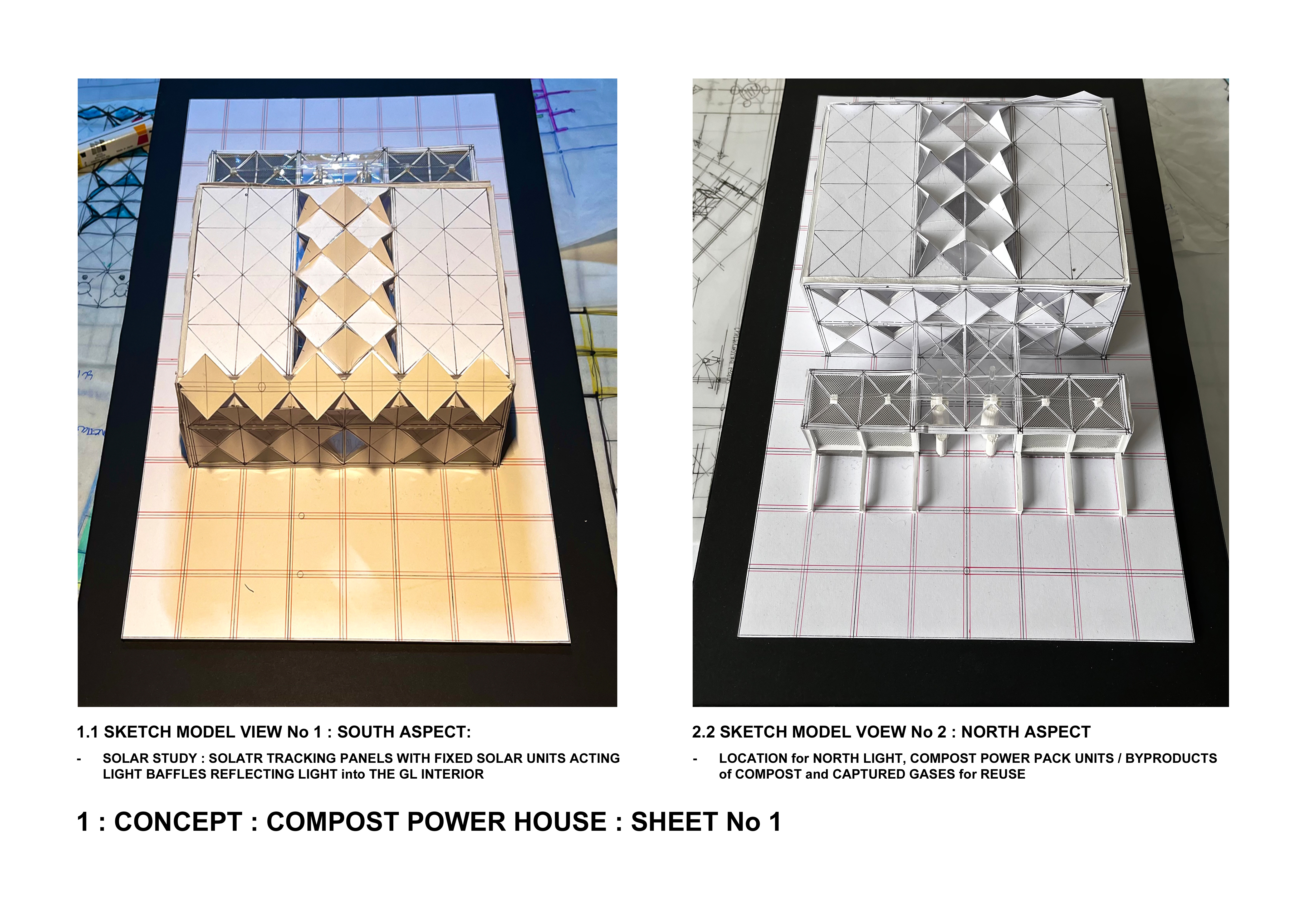

Environmentally, a basic north / south orientation maximises passive principles, minimising active systems. As weather patterns are unpredictable, this dual concept exploits free energy. To the north ‘Compost Power Units’, CPU’s (hot water / heating / by-products being compost / gases collected for reuse) to the south ‘Solar Tracker Energy Collectors with Fixed Roof Units’ processing energy (electricity / battery). The entire installation acts as singularity, whilst being part of a communal network sharing any surplus energy within the collective.

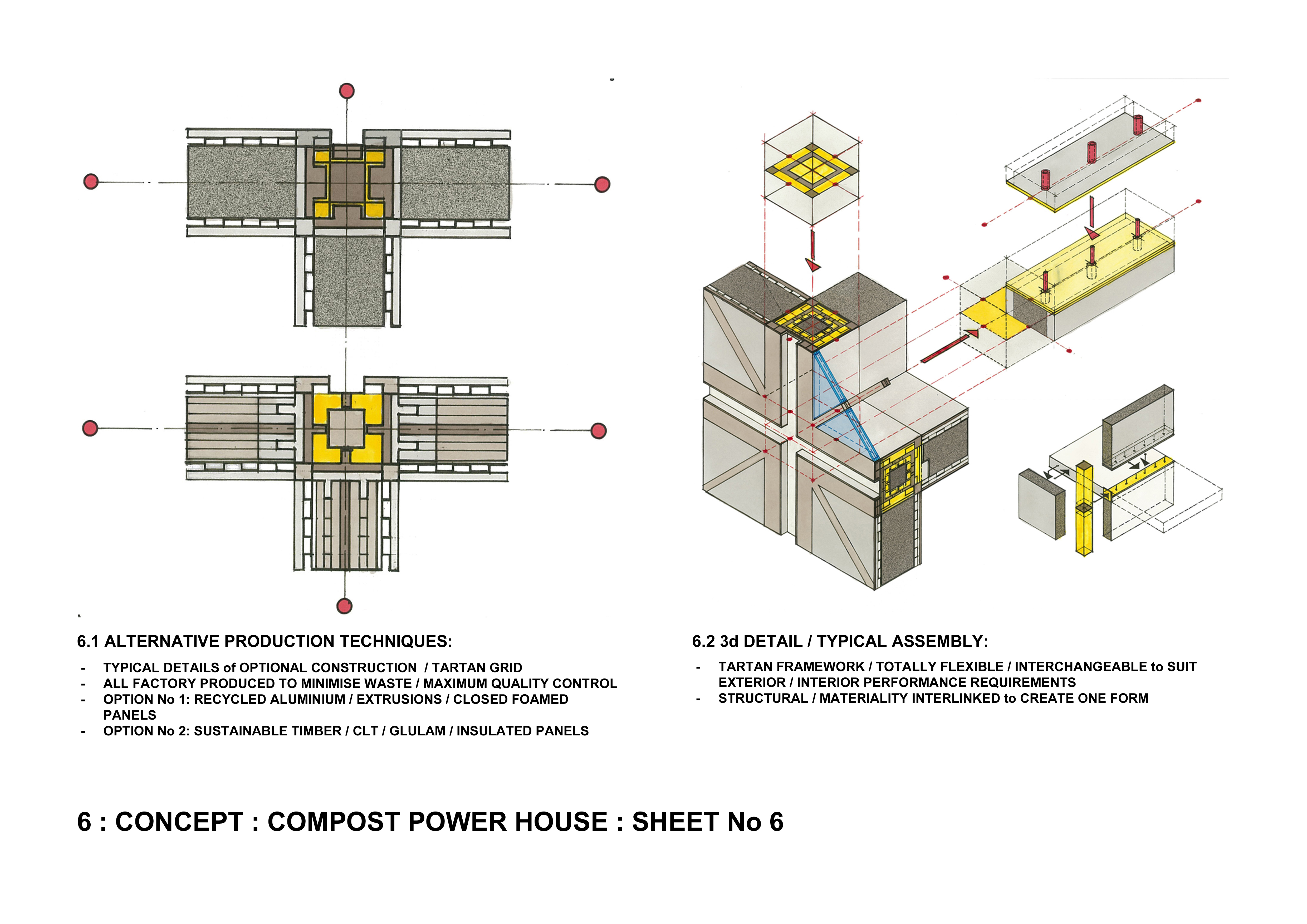

Technically, the house’s constructional assembly is routed in adaptable flexibility reacting to a personal brief, local climate and resources. Sustainability is core, with both aluminium / timber manipulated to work within in the same TDG parameters.

TECHNOLOGY & CONSTRUCTION:

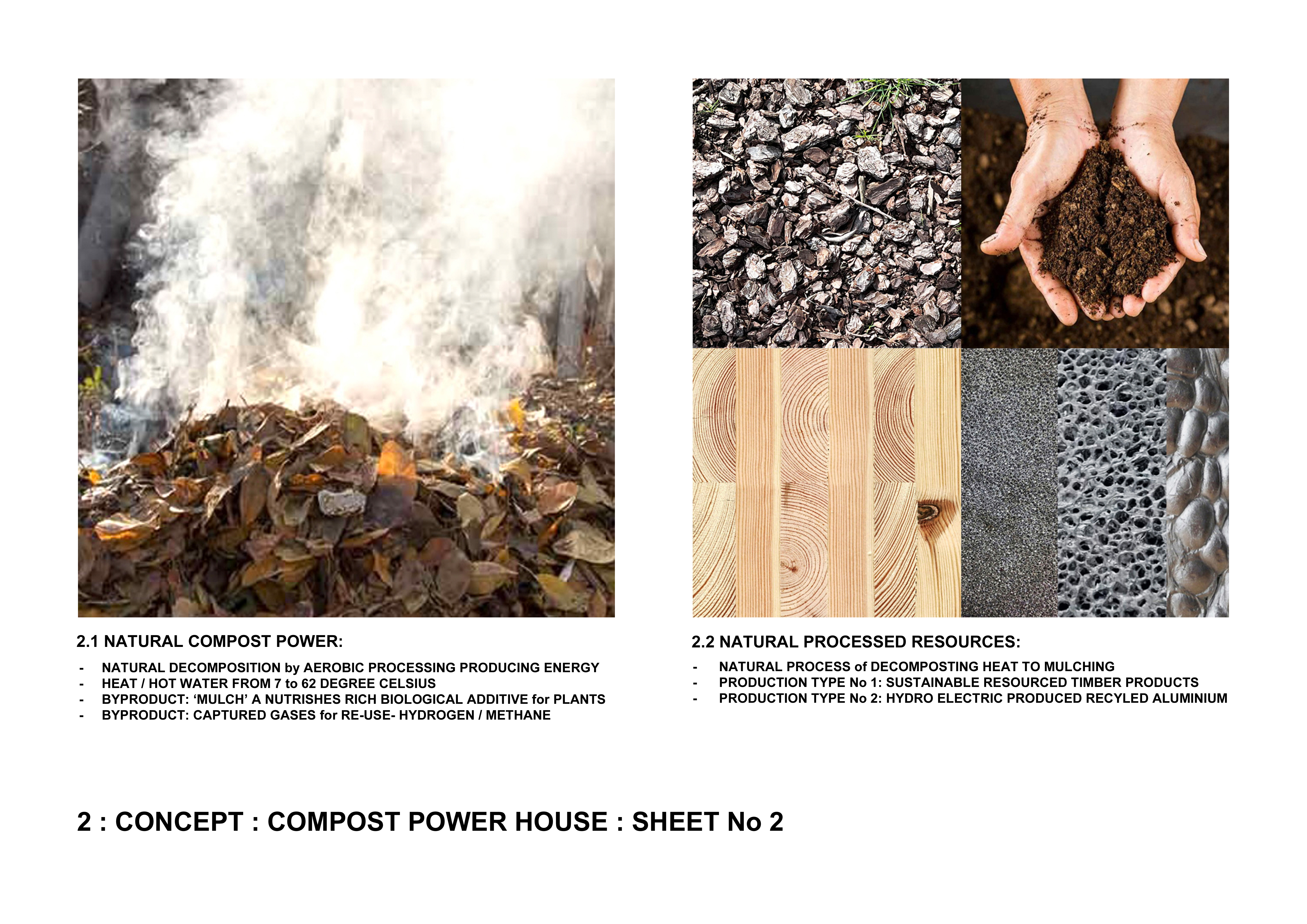

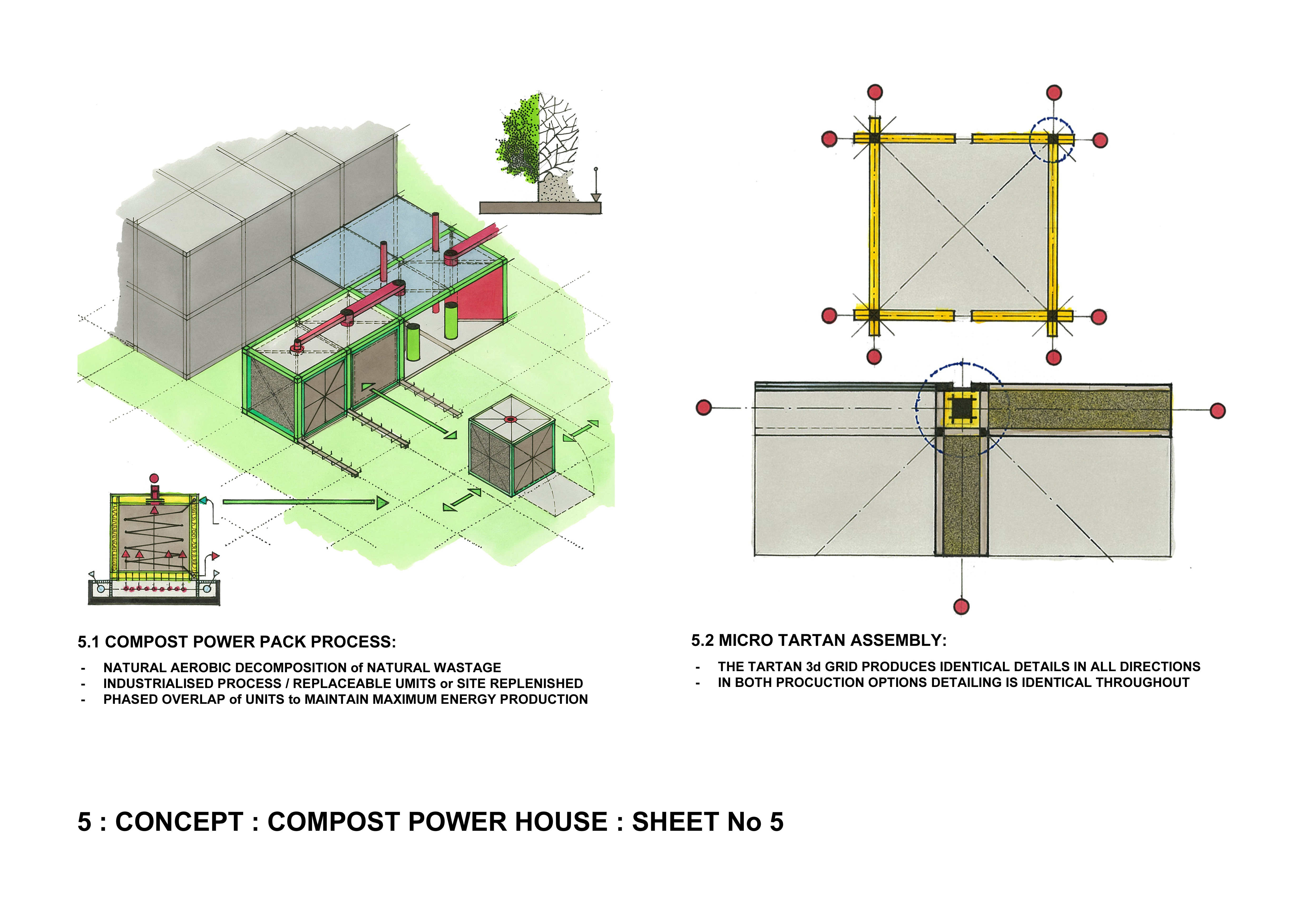

The CPU’s are based on the ‘Jean Pain Principles, Mulch’, a combination of organic matter such as bark / wood chips, leaves, straw and grass clippings transformed through the natural life cycle of ‘Aerobic Decomposition’ producing heat. It requires two phased interposed groups over a period of 11 - 12 months to avoid any energy lag. Hot water is circulated in a closed or open loop circuit consumed or stored via a heat exchanger. On exhaustion, units are either factory refitted with new mulch or reconstructed locally. The ‘Solar Tracker Panels’ constantly follow the sun for maximum energy collection, whilst the ‘Fixed Roof Units’ collect energy, whilst acting as solar baffles reflecting light through the glazed 1st floor illuminating the ground level.

Materially, ‘Hydroelectric Recycled Aluminium’ and ‘Sustainable Renewable Timber’ can’t be more further apart. TDG coordination exploits and controls the integration of structure, floors, walls, ceiling, roof and service components, capitalising on economies of scale, quality control, pre-assembly / testing, commissioning, recyclability of waste materials, limiting site operations reducing time both in assembly, decommissioning, reuse or recycling- the circular economy.

The ‘Compost Power House’ (CPH) explores a solution resolving todays shortages in housing. Firstly, it revisits the 1944 principles of ‘AIROH’, Mass Industrialised Housing’ created as an adaptable kit of parts. Secondly, the historic ‘Tartan Design Grid’ (TDG) and thirdly, the manipulation of ‘Aerobic Decomposition’ (composting).

Historically, TDG is seen in the Greek / Roman era, contemporary applied in urban planning and architecture. It superimposes layers forming the site plan, groundscape layout, spatial planning and constructional assembly. Low illumination activities are located at ground level (bedrooms, bathrooms, utilities.), higher ones at the 1st (family, living, guests.). The cellular rooms are formed by a structural panel system- material choices impacted through performance and wellbeing choices.

Environmentally, a basic north / south orientation maximises passive principles, minimising active systems. As weather patterns are unpredictable, this dual concept exploits free energy. To the north ‘Compost Power Units’, CPU’s (hot water / heating / by-products being compost / gases collected for reuse) to the south ‘Solar Tracker Energy Collectors with Fixed Roof Units’ processing energy (electricity / battery). The entire installation acts as singularity, whilst being part of a communal network sharing any surplus energy within the collective.

Technically, the house’s constructional assembly is routed in adaptable flexibility reacting to a personal brief, local climate and resources. Sustainability is core, with both aluminium / timber manipulated to work within in the same TDG parameters.

TECHNOLOGY & CONSTRUCTION:

The CPU’s are based on the ‘Jean Pain Principles, Mulch’, a combination of organic matter such as bark / wood chips, leaves, straw and grass clippings transformed through the natural life cycle of ‘Aerobic Decomposition’ producing heat. It requires two phased interposed groups over a period of 11 - 12 months to avoid any energy lag. Hot water is circulated in a closed or open loop circuit consumed or stored via a heat exchanger. On exhaustion, units are either factory refitted with new mulch or reconstructed locally. The ‘Solar Tracker Panels’ constantly follow the sun for maximum energy collection, whilst the ‘Fixed Roof Units’ collect energy, whilst acting as solar baffles reflecting light through the glazed 1st floor illuminating the ground level.

Materially, ‘Hydroelectric Recycled Aluminium’ and ‘Sustainable Renewable Timber’ can’t be more further apart. TDG coordination exploits and controls the integration of structure, floors, walls, ceiling, roof and service components, capitalising on economies of scale, quality control, pre-assembly / testing, commissioning, recyclability of waste materials, limiting site operations reducing time both in assembly, decommissioning, reuse or recycling- the circular economy.

MAIN MENU

MAIN MENU