THE ARCUS HOUSE

PROJECT INTRODUCTION:

This project was limited to ideas in the use of aluminium in the construction industry. It was commercially manufactured in 1827 with the Space Shuttle utilising 90% due its characteristics of lightness and strength. It does not rust or corrode & can be finished in many different colours and as a material it can be recycled time and time again- perfectly suitable for the choice in manufacturing components in such a project that views the house of the future.

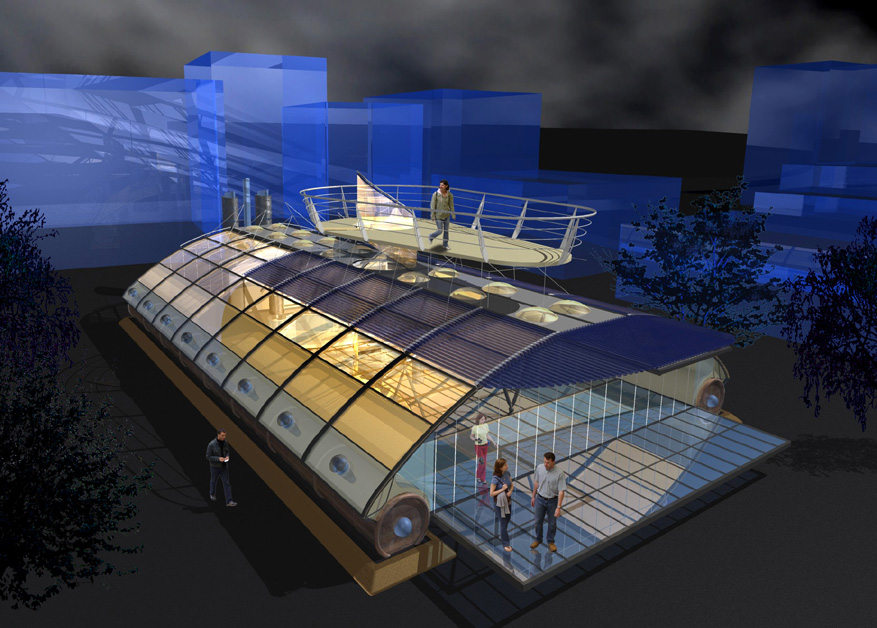

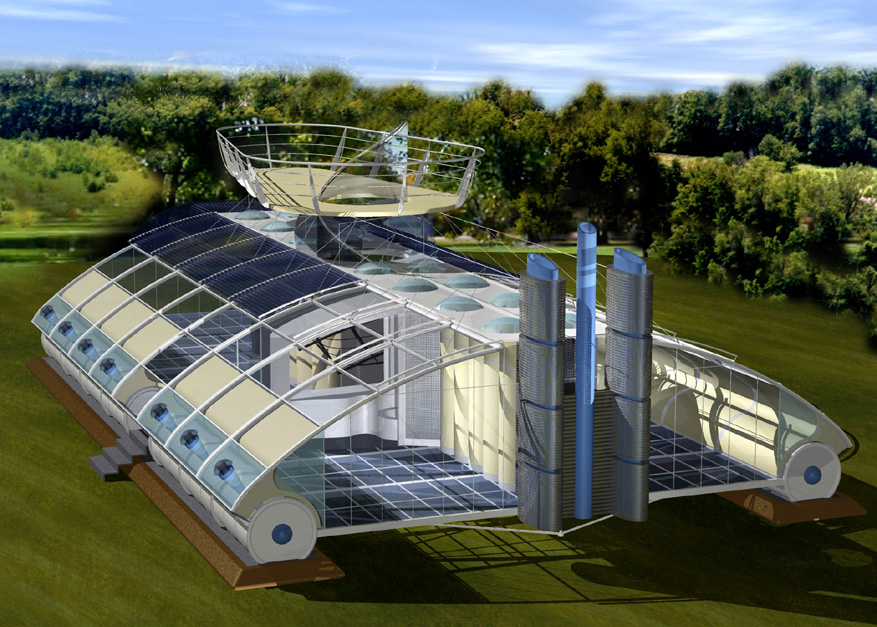

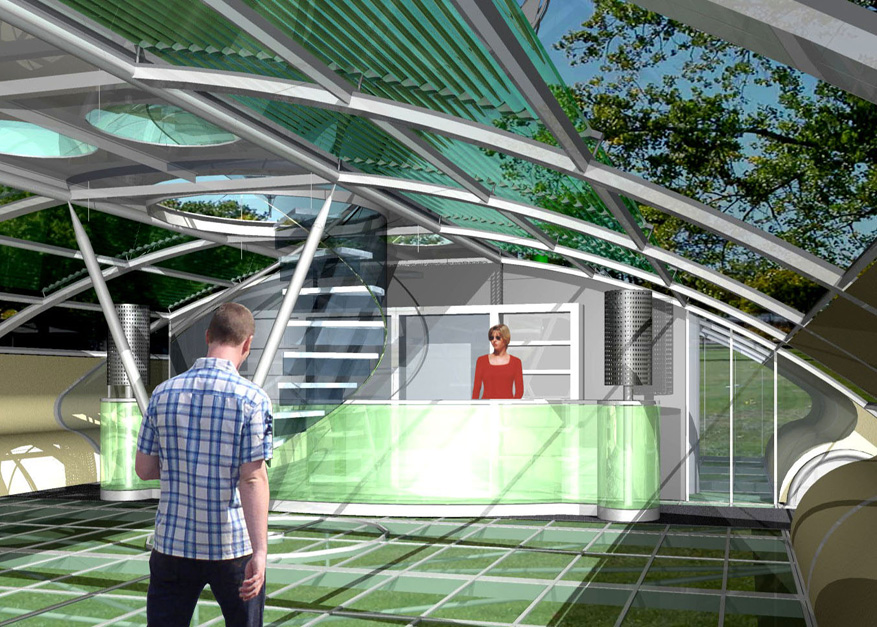

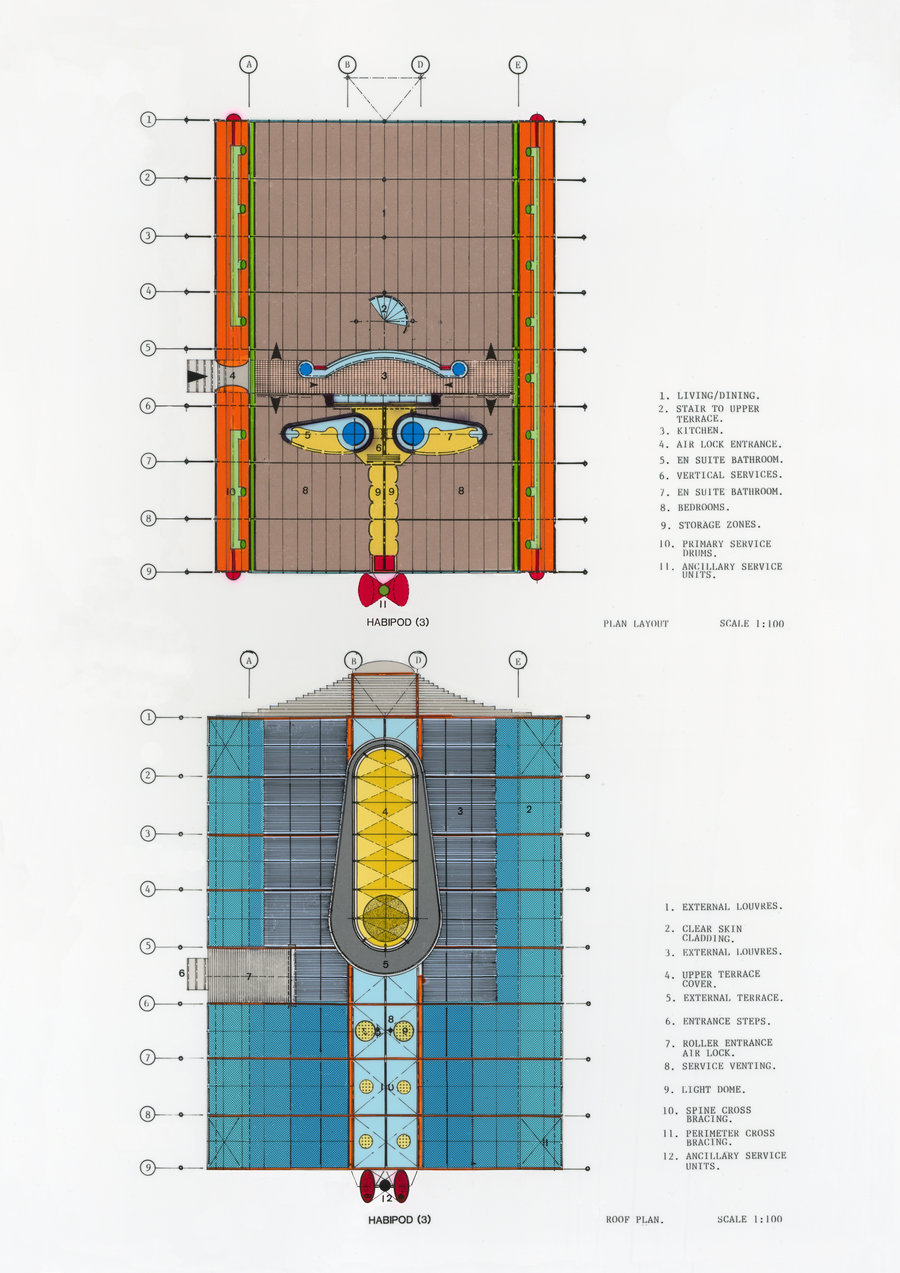

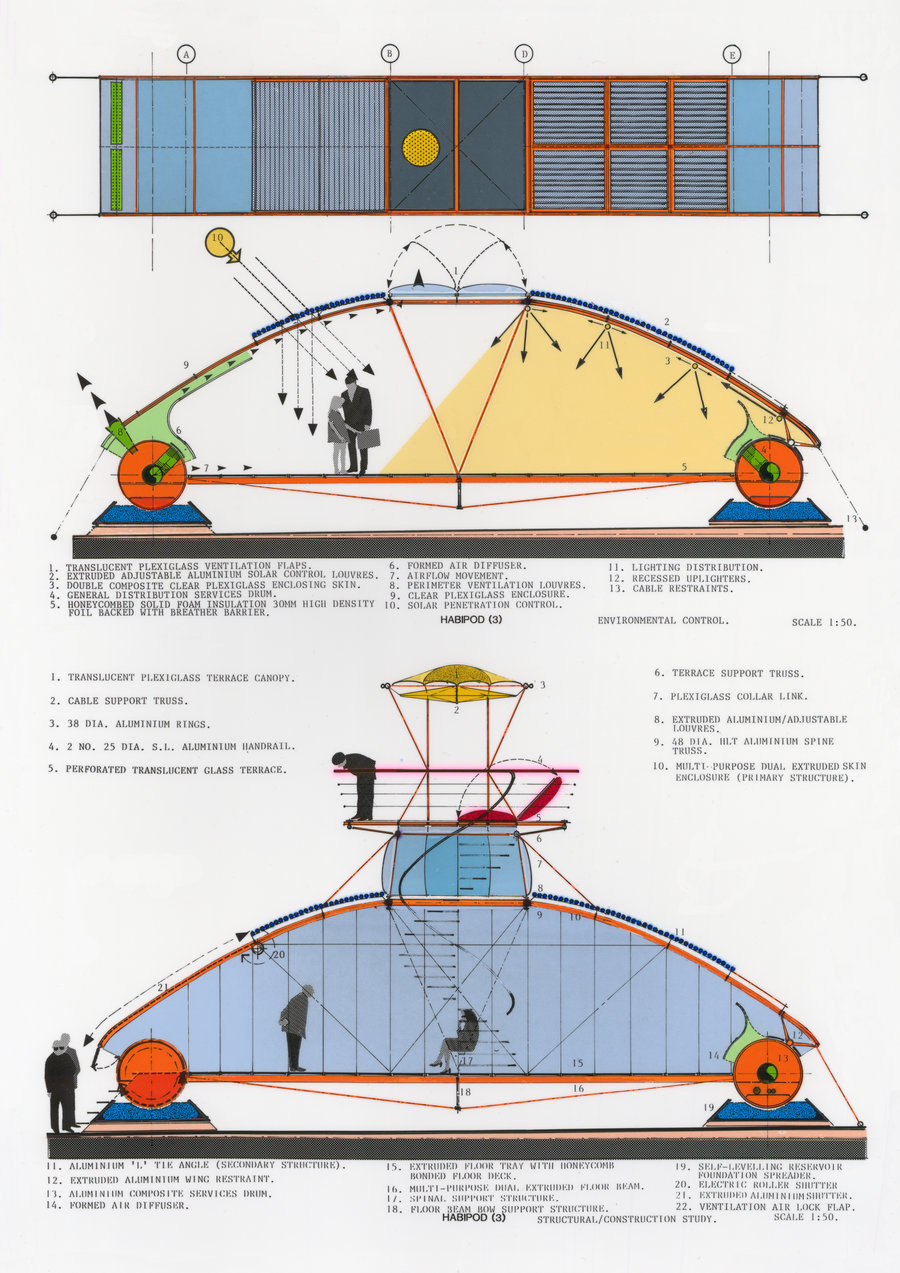

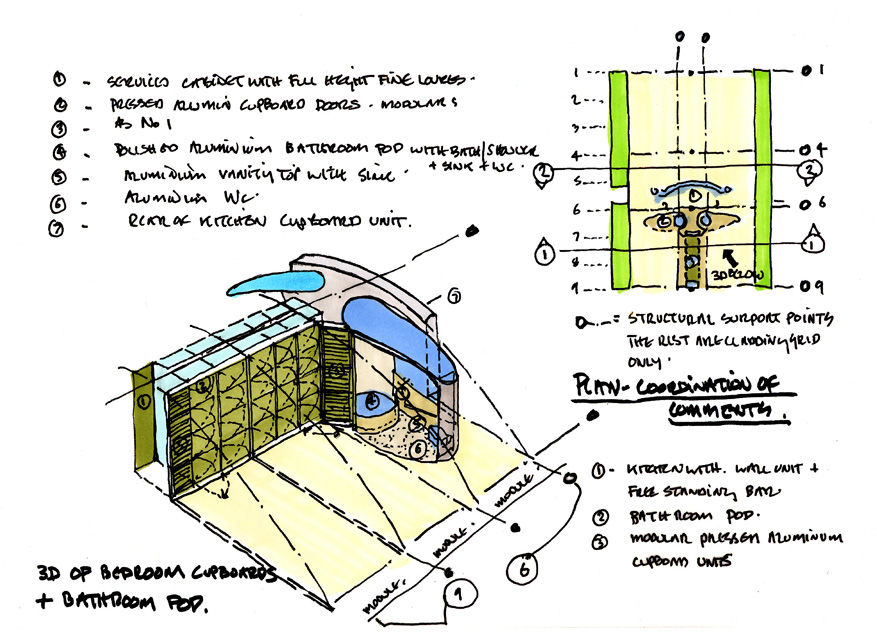

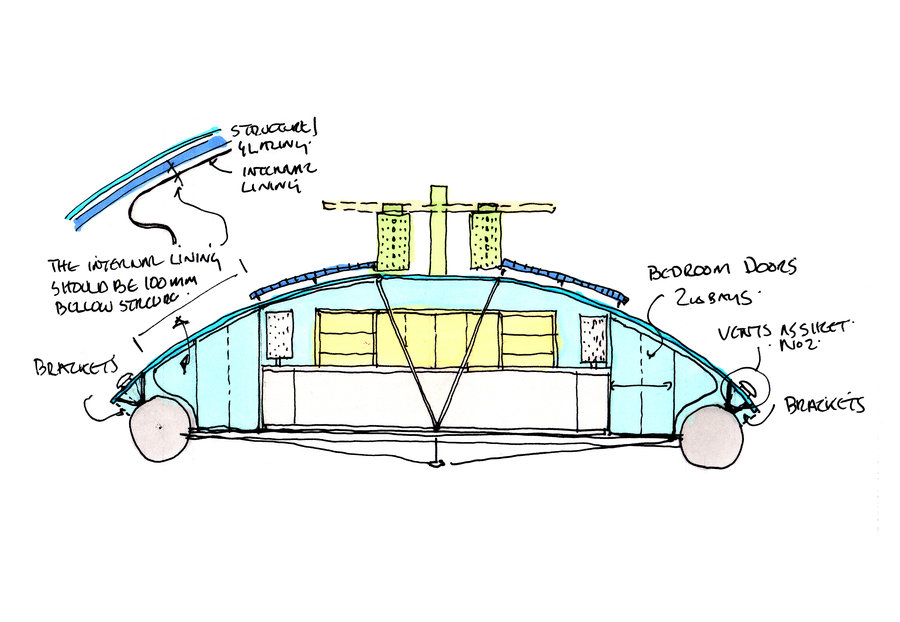

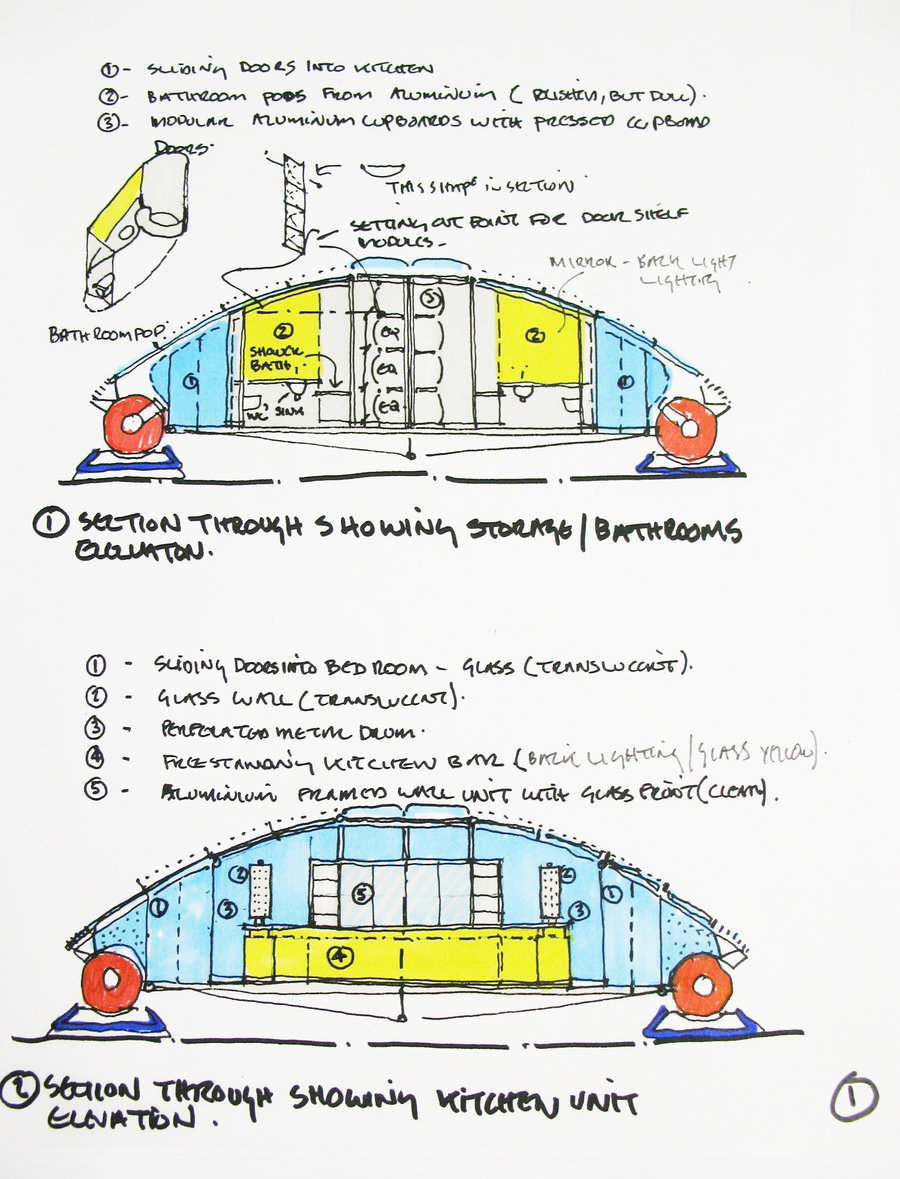

I took this opportunity to explore contemporary and future ideas in single and mass housing- always on the political agenda but never answered. The house consists of an open plan living/kitchen area, two bedrooms and en-suite bathroom pods. The sectional profile consists of service drum foundations with the apex consisting of continuous rooflight ventilators. The spaces between are filled either by solid, translucent or clear panels.

TECHNOLOGY & CONSTRUCTION:

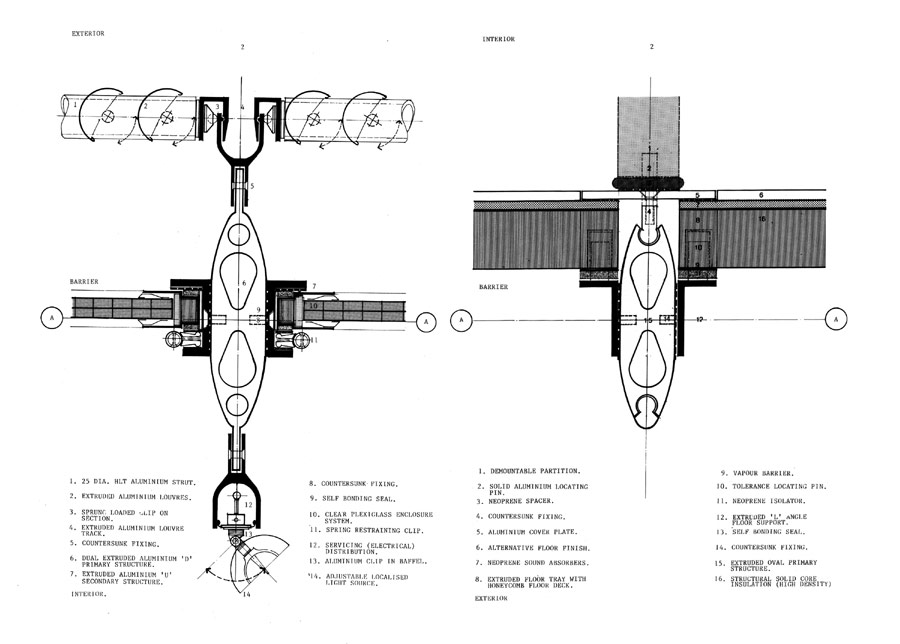

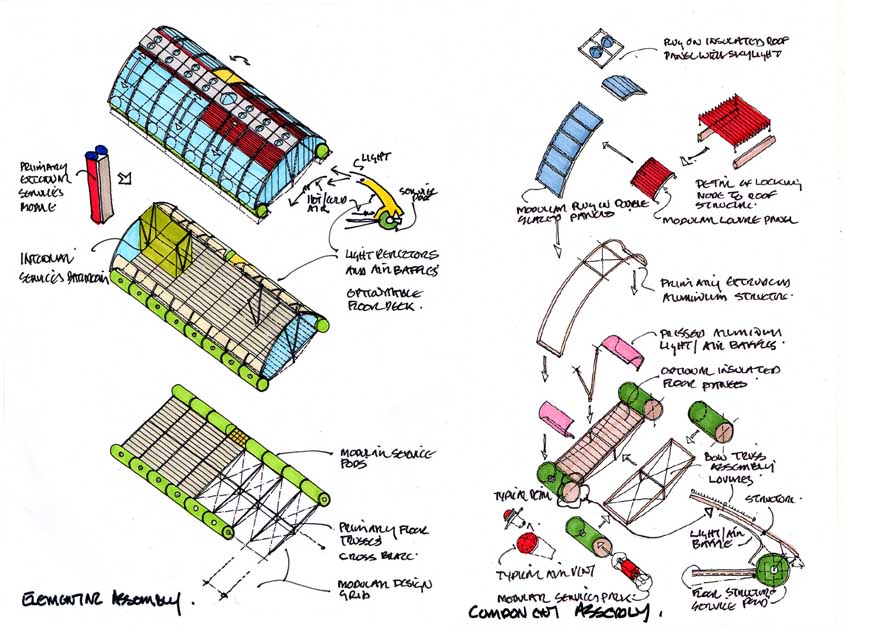

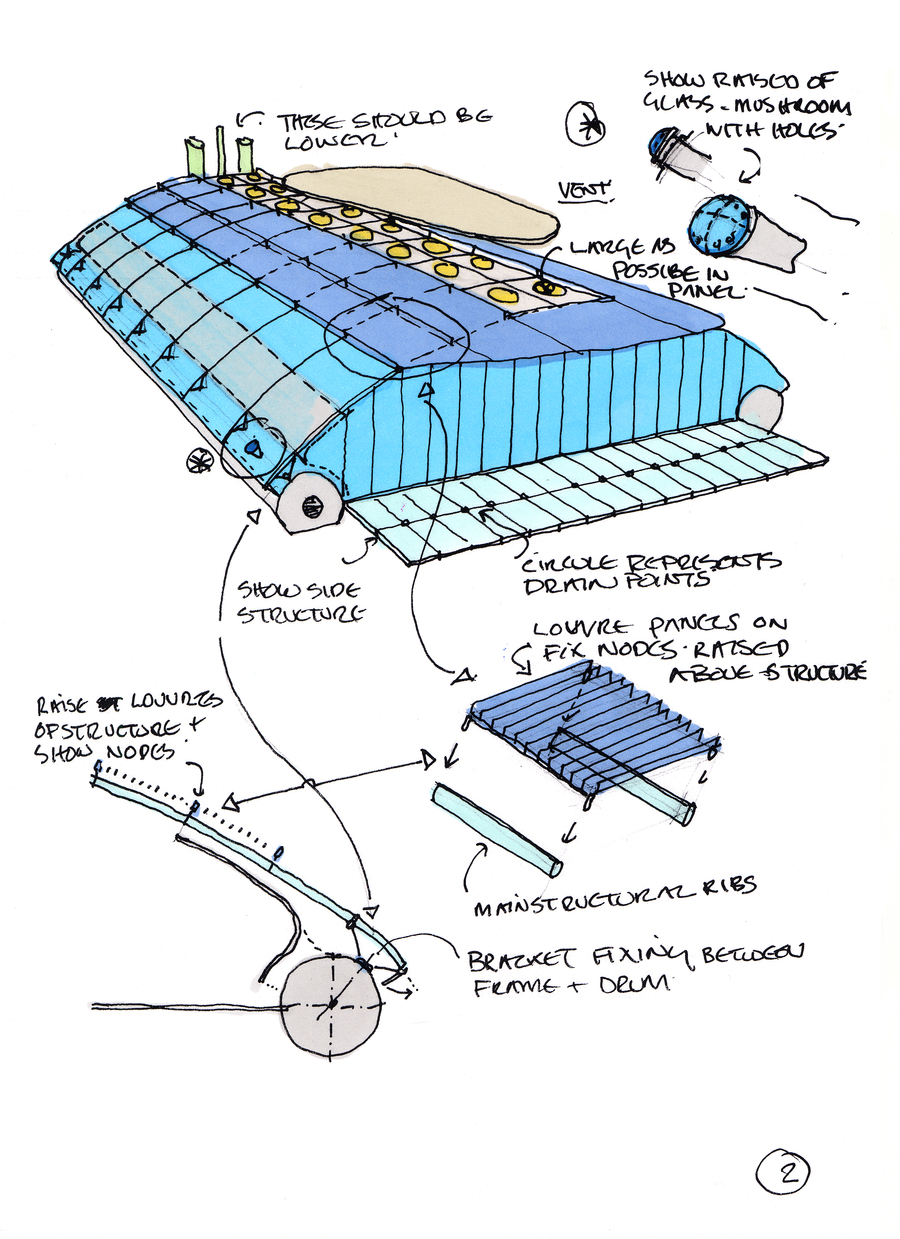

The concept superimposes function, environmental services and material fabric providing a flexible series of components that are suited for mass production and assemble techniques. A purpose designed extruded aluminium section was conceived as the principle structure forming curved roof and floor (2.4x9.6m grid). It accommodates external cladding, solar blinds, internal partitions, fixture, fittings and electrical installations such as lighting. The dwelling is envisaged as being entirely prefabricated in factory conditions with the minimum of site and wet trade operations (simple anchours and trough fluid foundations) the services foundation drums super structure, floor, cladding, furniture & fittings all providing a language viewed as a logical kit of parts with choices of materials and finishes.

Environmentally, the external skin consists of high performance glazing fitted with external, adjustable and stackable shading or insulted aluminium panels. The houses profile & form naturally allows heat and air to rise from the perimeter to the higher rooflight being expelled at the apex- natural air conditioning. The dwelling’s modular spatial grid system also incorporates services packs located in the drum foundations they are specifically designed to deal with the modular zone air of the building grid.

I view this house has being a development and reaction to the every day tradition. It has it’s own architectural aesthetic born from fulfilling its functional requirements, using manufacturing & assembly techniques expressed as an architectural aesthetic providing a new fresh look in the simple term home.

This project was limited to ideas in the use of aluminium in the construction industry. It was commercially manufactured in 1827 with the Space Shuttle utilising 90% due its characteristics of lightness and strength. It does not rust or corrode & can be finished in many different colours and as a material it can be recycled time and time again- perfectly suitable for the choice in manufacturing components in such a project that views the house of the future.

I took this opportunity to explore contemporary and future ideas in single and mass housing- always on the political agenda but never answered. The house consists of an open plan living/kitchen area, two bedrooms and en-suite bathroom pods. The sectional profile consists of service drum foundations with the apex consisting of continuous rooflight ventilators. The spaces between are filled either by solid, translucent or clear panels.

TECHNOLOGY & CONSTRUCTION:

The concept superimposes function, environmental services and material fabric providing a flexible series of components that are suited for mass production and assemble techniques. A purpose designed extruded aluminium section was conceived as the principle structure forming curved roof and floor (2.4x9.6m grid). It accommodates external cladding, solar blinds, internal partitions, fixture, fittings and electrical installations such as lighting. The dwelling is envisaged as being entirely prefabricated in factory conditions with the minimum of site and wet trade operations (simple anchours and trough fluid foundations) the services foundation drums super structure, floor, cladding, furniture & fittings all providing a language viewed as a logical kit of parts with choices of materials and finishes.

Environmentally, the external skin consists of high performance glazing fitted with external, adjustable and stackable shading or insulted aluminium panels. The houses profile & form naturally allows heat and air to rise from the perimeter to the higher rooflight being expelled at the apex- natural air conditioning. The dwelling’s modular spatial grid system also incorporates services packs located in the drum foundations they are specifically designed to deal with the modular zone air of the building grid.

I view this house has being a development and reaction to the every day tradition. It has it’s own architectural aesthetic born from fulfilling its functional requirements, using manufacturing & assembly techniques expressed as an architectural aesthetic providing a new fresh look in the simple term home.

MAIN MENU

MAIN MENU